Step-by-Step Guide to Flawless Car Park Whole Lot Striping

Making sure precision and durability in auto parking great deal striping demands a systematic technique that begins with thorough surface area prep work and calculated layout preparation. The selection of materials and tools calibration are essential elements in attaining a perfect finish.

Surface Preparation

Proper surface area preparation is important for achieving long lasting and top quality vehicle parking whole lot striping results. Prior to beginning the striping procedure, it is essential to make sure that the surface is clean, completely dry, and devoid of any kind of debris, oil, or dirt that can affect the attachment of the paint. This can be achieved with brushing up the area completely, making use of a pressure washing machine if necessary, and enabling ample time for the surface to completely dry totally.

Along with sanitation, the condition of the surface itself plays a substantial duty in the durability of the striping. Any type of existing splits, splits, or unequal locations ought to be properly repaired and leveled before using the paint. This not just ensures a smoother and much more professional-looking surface yet also assists protect against premature wear and tear of the red stripes due to underlying surface issues.

Additionally, it is crucial to consider the weather conditions when preparing the surface area for striping. Preferably, the surface area needs to be completely dry and the weather report ought to suggest no rainfall for a minimum of 24-hour after removing to allow the paint to cure properly. By paying very close attention to surface prep work, you established the structure for a perfect parking area striping task that will stand the test of time.

Layout Planning

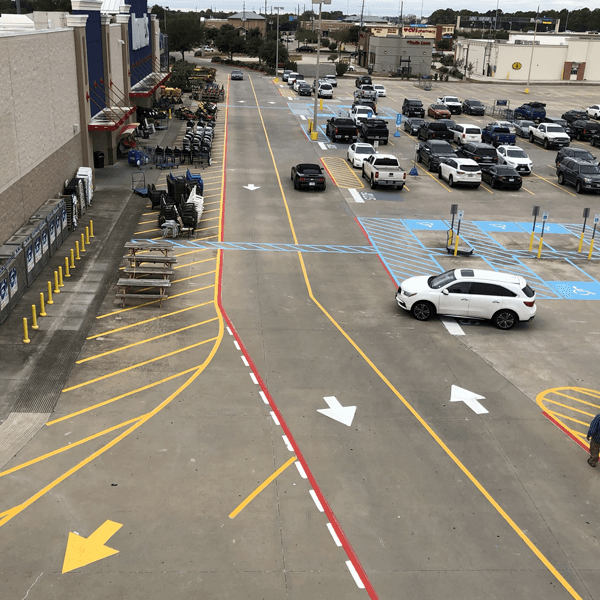

A strategic layout planning procedure is vital to making certain optimum functionality and performance in parking area striping jobs. Prior to beginning the real striping procedure, it is critical to very carefully plan the design to maximize using room and make sure a smooth flow of web traffic. The primary step in design planning is to analyze the parking area's dimensions and layout to establish the variety of vehicle parking spaces required and the very best way to prepare them.

Take into consideration aspects such as the size and types of cars that will certainly be utilizing the car parking whole lot, any type of marked areas for impaired auto parking, and any details guidelines or requirements that require to be followed (Asphalt Patching). When these factors have actually been considered, develop an in-depth plan that lays out the placement of car parking spaces, aisles, entries, leaves, and any type of other needed markings

Product Option

Choosing the suitable materials for parking great deal striping is a critical element of making certain toughness and visibility for durable results. When it concerns product selection, 2 primary choices are generally utilized: paint and polycarbonate.

Paint, oil-based or commonly water-based, is a cost-efficient choice for striping jobs. Water-based paint is eco friendly and dries out quickly, making it appropriate for tasks where time is a problem.

Polycarbonate striping, made of synthetic material materials, supplies remarkable sturdiness and visibility compared to repaint. Thoroughly consider your task's requirements and budget plan when choosing the most ideal you could try here striping material.

Devices Arrangement

When setting up devices for car park striping, making sure correct calibration and alignment is essential to attaining precise and professional outcomes. The initial step in devices arrangement is to calibrate the striping equipment according to the manufacturer's guidelines. Asphalt Patching. This entails readjusting the equipment's setups for paint flow rate, line width, and pressure to make sure accurate and constant lines

Following, it is vital to examine the alignment of the striping maker to guarantee consistent and straight lines. This can be done by using a laser guide or determining tape to note the beginning point and ensure the device follows a straight path throughout the striping procedure.

Additionally, examining the problem of the striping devices, such as the spray nozzles and paint reservoir, is essential to avoid any disruptions during striping. Cleansing and keeping the tools regularly will help stay clear of obstructions and make sure smooth operation.

Striping Execution

When applying the paint, make smooth and also passes with the striping machine to prevent any smudging or uneven lines. Bear in mind any obstacles or corners that might call for mindful handling to preserve the straightness of the stripes. Additionally, always follow the fixed format strategy to ensure harmony throughout the car park.

Final Thought

In verdict, achieving perfect parking area striping calls for meticulous surface preparation, cautious format preparation, correct material selection, accurate tools configuration, and constant implementation. Adhering to these actions vigilantly guarantees a resilient and top quality result. By concentrating on each stage of the process with interest to information and accuracy, car park whole lot striping can be finished successfully and web properly.

Ensuring accuracy and durability in car park whole lot striping requires an organized technique that starts with careful surface preparation and tactical format preparation.A calculated design planning process is key to ensuring optimum functionality and effectiveness in car parking great deal striping jobs.When setting up tools for auto parking lot striping, making certain correct calibration and positioning is vital to accomplishing professional and precise results.To accomplish professional and specific car park great deal striping results, precise implementation of the striping process is vital.In conclusion, attaining perfect parking whole lot striping needs meticulous surface area preparation, mindful design planning, proper material option, accurate tools configuration, and regular execution.